The excellent composite properties result from the PEEK matrix, the full wetting and tailored fiber matrix interface achieved in the impregnation process.Concordia’s unique process intimately blends unsized continuous filament carbon fiber with unsized continuous filament thermoplastic fibers to produce a yarn that can be woven or braided into fabrics. Commingling is a process for producing highly flexible thermoplastic prepregs.

They are mainly used in the manufacturing of electronic machines, transformers and generators, to function as a consolidation for windings and as bonding.

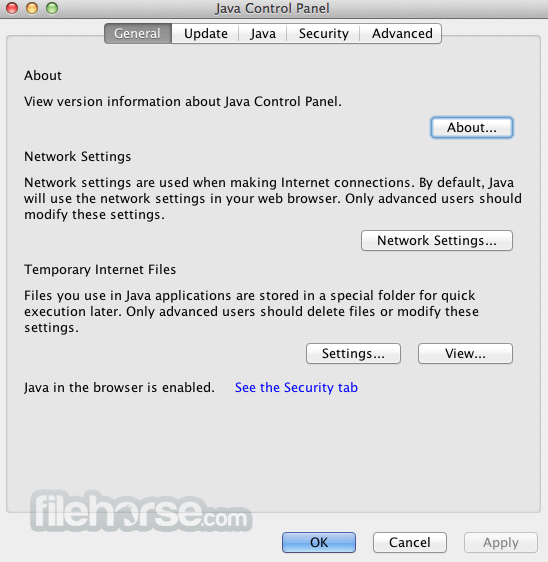

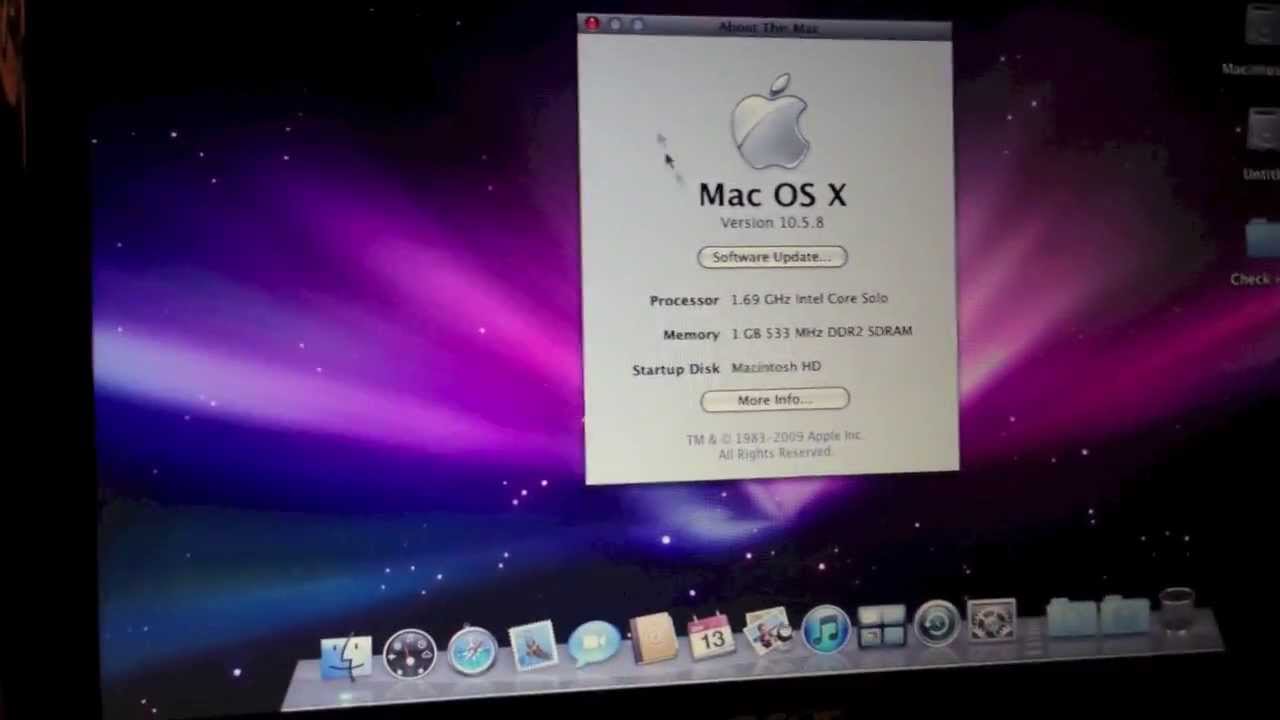

Java for mac 10.6.8 download pdf#

Check Pages 1 - 9 of APC -2-PEEK Thermoplastic Polymer - Cytec Industries in the flip PDF version.You can search for the details page that incorporates the necessary information, such as by searching the temperature, pressure or speed, the corresponding products by fluid or the equivalent products from other companies, according to the valve and each device.Conventional BMI resin-impregnated prepreg is already used for high-temperature applications such as aerospace engine components to prevent degradation and deformation, however, it normally loses its impact resistance when heat resistance is increased. Prepregs are generally impregnated with lightweight, high-intensity epoxy resin.Very high temperature semi-crystalline polymer with good combination of toughness, chemical solvent resistance, low moisture absorption, and FST properties.

0 kommentar(er)

0 kommentar(er)